PROJECT KEA

RESOURCE RECOVERY OR RESOURCE DESTRUCTION?

South Island Resource Recovery Limited (SIRRL)

The company name suggests recovering resources, but is it? Burning materials that could otherwise be recycled, reused or repurposed is not recovery.

SIRRL has stated that it will not burn recyclables in the plant. However, the waste feedstock table provided in its resource consent suggests otherwise.

It is anyone’s guess just how SIRRL proposes keeping recyclables out of the feedstock, as they have yet to provide details. However, they have stated that there will be no sorting at the plant before incineration.

The company’s resource consent states that they will use 2.5 million litres of water, large amounts of diesel, and numerous chemicals daily in the processing of waste.

BURNING PLASTIC

Resource recovery? Resource destruction would be a more accurate term. The feedstock will contain large amounts of plastic. Plastic contains toxic material, which is released when incinerated. To avoid these toxins being released into the atmosphere, filters, scrubbers, and yet more resources are required.

Plastic, essentially low-grade oil, is a valuable component in the waste-to-energy process. Its high calorific value means burning it yields a high energy return, leading to increased revenue.

Plastic plays a crucial role in the Waste-to-energy process. Without it, more auxiliary fuel, such as diesel, would be needed to maintain the furnace at the required minimum temperature of 850 degrees Celsius.

Plastic waste requires a lot of energy in its manufacture and distribution before becoming a waste product. This embodied energy is important in determining its value as a resource. Achieving a net energy gain requires returning more energy from destruction than is used in its manufacture to disposal.

Waste-to-energy is not only a very polluting but also an inefficient form of energy generation. Sweden, for example, has 34 W-t-E plants, which account for only 4% of its total energy generation.

DESTROY 2.5 MILLION LITRES OF WATER PER DAY

Fresh water is one of the most precious resources available. Using 2.5 million litres per day would surely need to be worth it. But is it? transforming huge amounts of freshwater into water vapour, known to be a potent greenhouse gas, and releasing it into the atmosphere in an attempt to produce a modest amount of energy could hardly be described as innovative.

New Zealand’s electricity is currently around 82% renewable, which is increasing constantly. Most of that electricity is generated by hydroelectricity, like wind and solar, harnesses a natural resource without destroying it in the process, unlike waste incineration, coal, or gas-fueled power stations that rely on the extraction and destruction of resources, releasing climate-changing emissions in the process.

AGGREGATE RECOVERY

Burning waste creates ash, and Project Kea will produce 100,000 tonnes of it annually. SIRRL has stated that they will recover aggregate from the residue ash and recycle it into a roading or construction material. However, their resource consent states they intend to landfill 100,000 tonnes annually. The company’s has stated its future intention is to repurpose the ash into an aggregate, but this has some significant obstacles to overcome first. There is current regulation in place in NZ prohibiting the reuse of ash. To overcome this, the company would need to prove that the ash is safe and suitable for alternative purposes, highlighting the crucial need for proper processing and regulation.

Waste-to-energy ash repurposed into aggregate for roading has been achieved in some European countries, however, each country has its regulations and requirements before that can be realised.

The danger of using this material in roading or as a construction material is its leachate risk. WTE ash contains toxic material, which can leach out of whatever material it is introduced into, including concrete, over time and become an environmental and human health risk.

Best practices for processing WTE ash into aggregate involve washing the ash to remove the toxic material and maturing the ash to lower its pH levels.

The image below shows the HEROS waste to energy ash to aggregate operation located in Sluiskil in the Netherlands. This 45-hectare site is used to process around 700,000 tonnes of ash annually. Although the HEROS plant processes about 7 times the amount of ash Project Kea will produce, the involved process needed to remove the toxic material from the ash remains the same.

landfilling 100,000 tonnes of toxic ash each year!

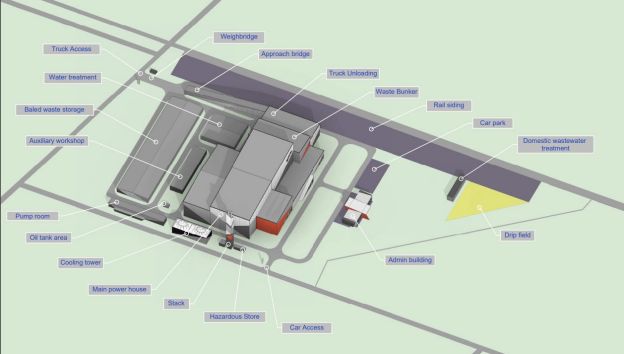

The Project Kea resource consent application does not mention aggregate processing on-site or anywhere else. If SIRRL’s future plan is to reuse the ash as an aggregate without processing it, then this is a major concern. Below is a plan taken from the SIRRL resource consent application. As you can see, there are no provisions for ash processing on the 15-hectare Project Kea site.

SIRRL has argued the virtues of WTE against the current waste disposal practice of landfilling, yet their proposal relies on landfilling 100,000 tonnes of ash annually.